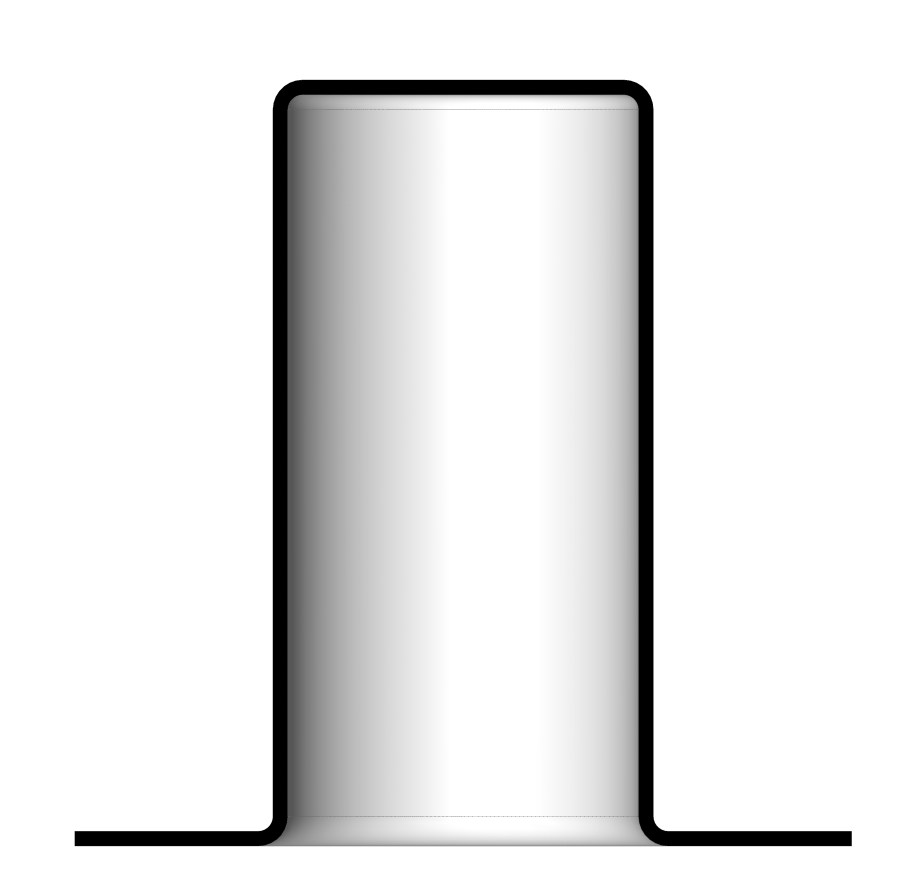

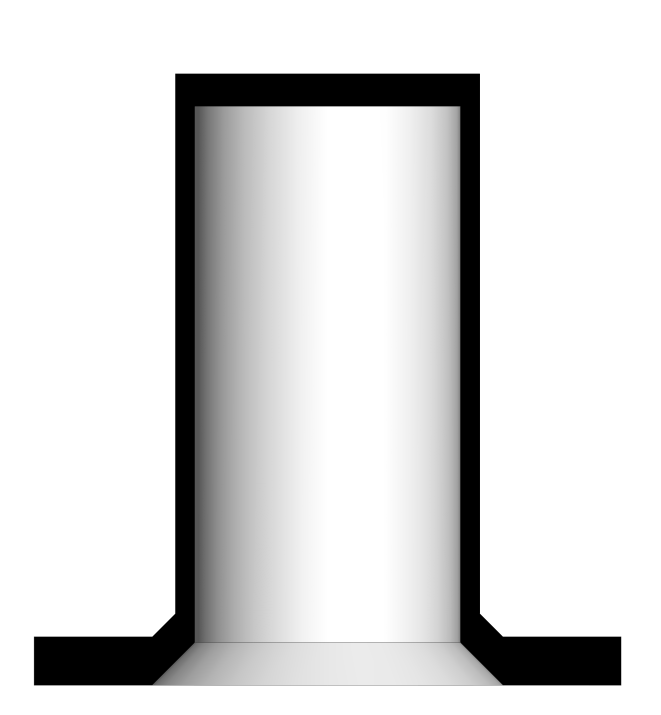

Deep drawing is a kind of metal stamping and one of the most popular methods in sheet metal production with multiple applications. This article explains when you should choose deep drawing and how it compares to metal machining techniques. With deep drawing, a flat sheet can be deformed to a three-dimensional product. For a further explanation of the deep drawing technique please see this post.

6 reasons to choose for micro deep drawing.

Micro deep drawing is used in many applications like medical disposables or sensor housings. It is a technique widely used in the automotive, electronic, optical, aural and medical industries. This can be ascribed to the benefits of deep drawing listed below.

1. Scalable. Deep drawn products are easily scalable and extremely suitable for big production volumes.

2. Economical. After the initial tooling investment, the production costs are low.

3. Stable. The production process is very stable and has little fluctuation in dimensions.

4. Low waste. Deep drawing is very material-efficient. During forming little material is removed.

5. Seamless. While deep drawing products are made out of one piece of sheet. It has no seams, transitions or weaknesses.

6. High strength. During the forming process, the material is being cold worked which results in higher tensile strength and stronger products.

7. Wall thickness. Very thin wall thicknesses are possible. This can, for example, have benefits with sensors that need to detect temperature fluctuations fast and accurate.

Micro deep drawing vs machining

In general, there are some fundamental differences between deep drawing and machining.

Deep drawing |

Machining |

|

| - Deep drawing is a technique were sheet is being deformed to three-dimensional product. | - With machining, material is removed from massive plates or bars to come to an end product which can be three dimensional. Most popular techniques are milling and turning. | |

| - It is a fast process that makes it suitable for big production volumes. | - Good for low volumes and prototyping. | |

| - Initial costs can be high due to investments in engineering and tooling | - Low initial cost. Only setup costs | |

| - Micro deep drawing has a good cost/ benefit ratio. | - Big volumes have low advantages in scalability due to relatively long cycle times. | |

| - Deep drawn products are light but strong due to the deformation of the sheet during the process. | - Product weight is normally higher than produced with deep drawing | |

| - Complex geometries are possible within the physical boundaries of deep drawing | - Very complex geometries are possible due to advanced CNC machinery. | |

| - Developing deep drawn products requires a good understanding of the process by the engineer. | - Engineering for machining requires less knowledge of the process due to the extensive possibilities CNC machinery has. | |

|

|

Conclusion

If a metal product needs to be designed and a production technique needs to be chosen. It is important to first look at the expected quantities. If it needs to be made in bigger volumes deep drawing can be a good choice.

Below a summary of the most important arguments for choosing deep drawing.

1. With bigger volumes (Already starting at 100 pcs)

2. With very thin wall thicknesses. Micro deep drawing gives the possibility to deform material of less than 20 microns.

3. When products need to be seamless

4. With three-dimensional asymmetric shapes

5. When the product needs to be light and strong

Do you want to know what deep drawing can do for your business? Please contact us!