What is deep drawing?

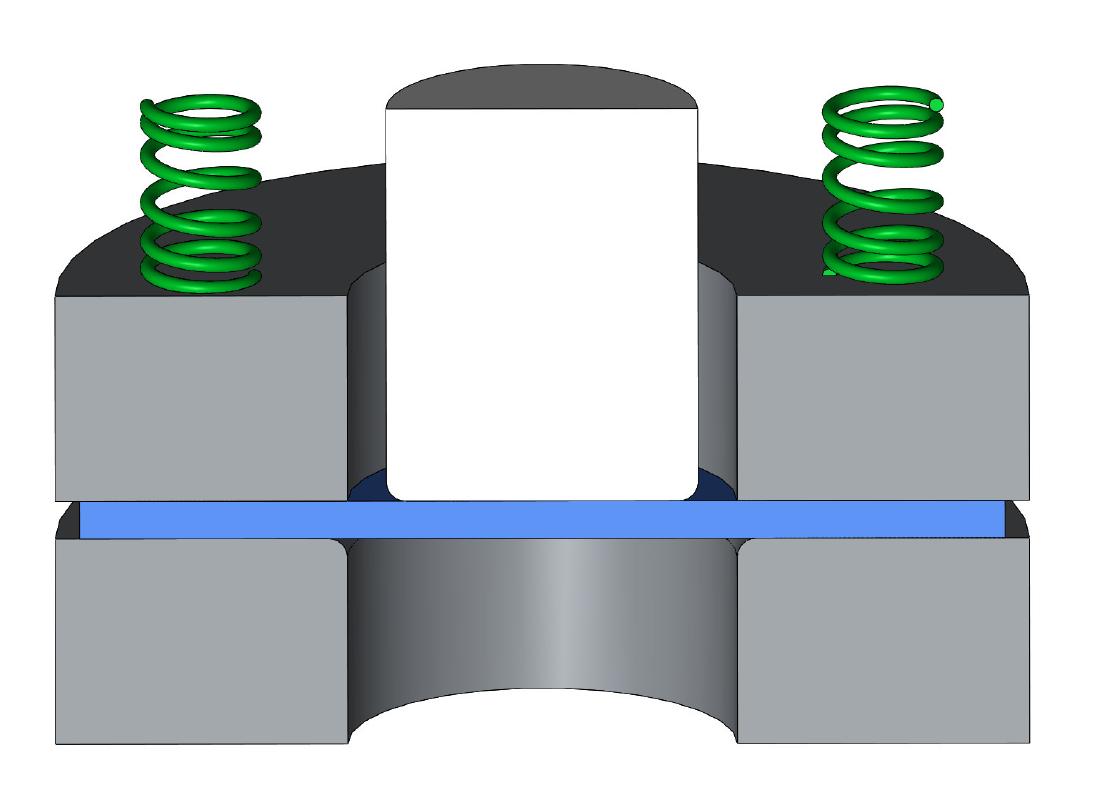

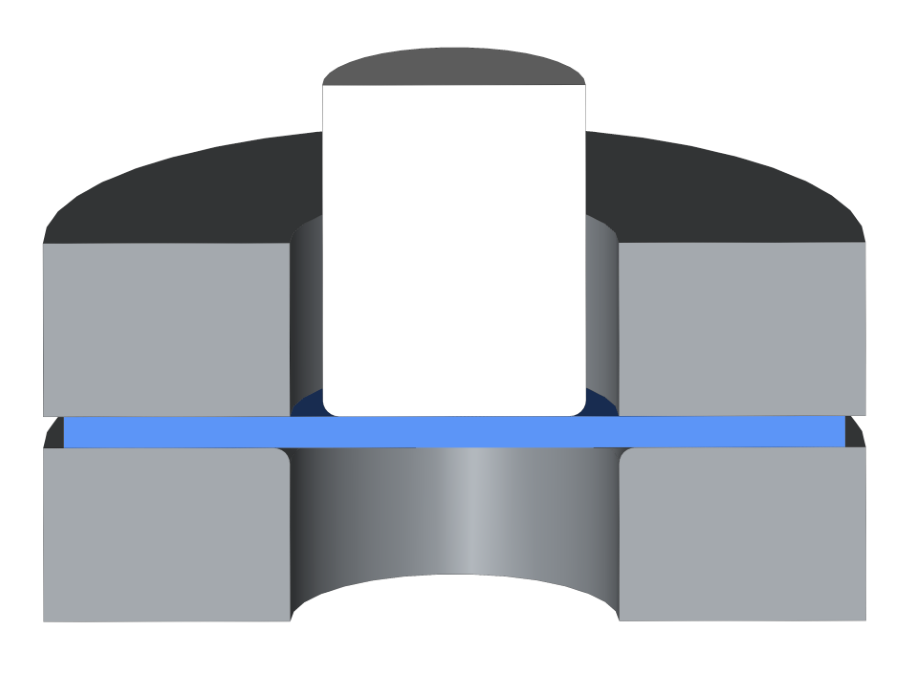

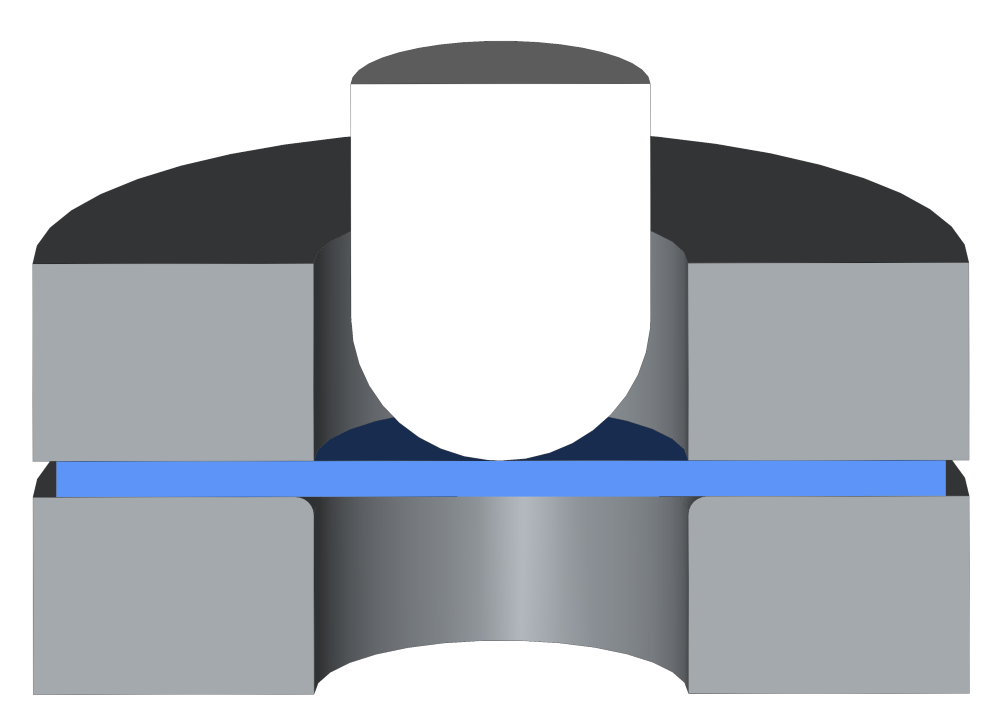

Deep drawing is a forming technique in which metal sheet is transformed under mechanical pressure by plastic deformation into a seamless three-dimensional shape. A draw ring is used, whose contour is the same as the outside of the product to be manufactured. In addition, there is a mandrel, which has an opposite shape and thus fits into the draw ring. The material to be machined, the plating, is placed on the pull ring and held by a bending holder with spring pressure. A press then pushes the mandrel down and the platine is pressed into the shape of the draw ring.

Deep drawing versus stretching

Many people confuse deep drawing with stretching; however, there is a fundamental difference between these techniques.

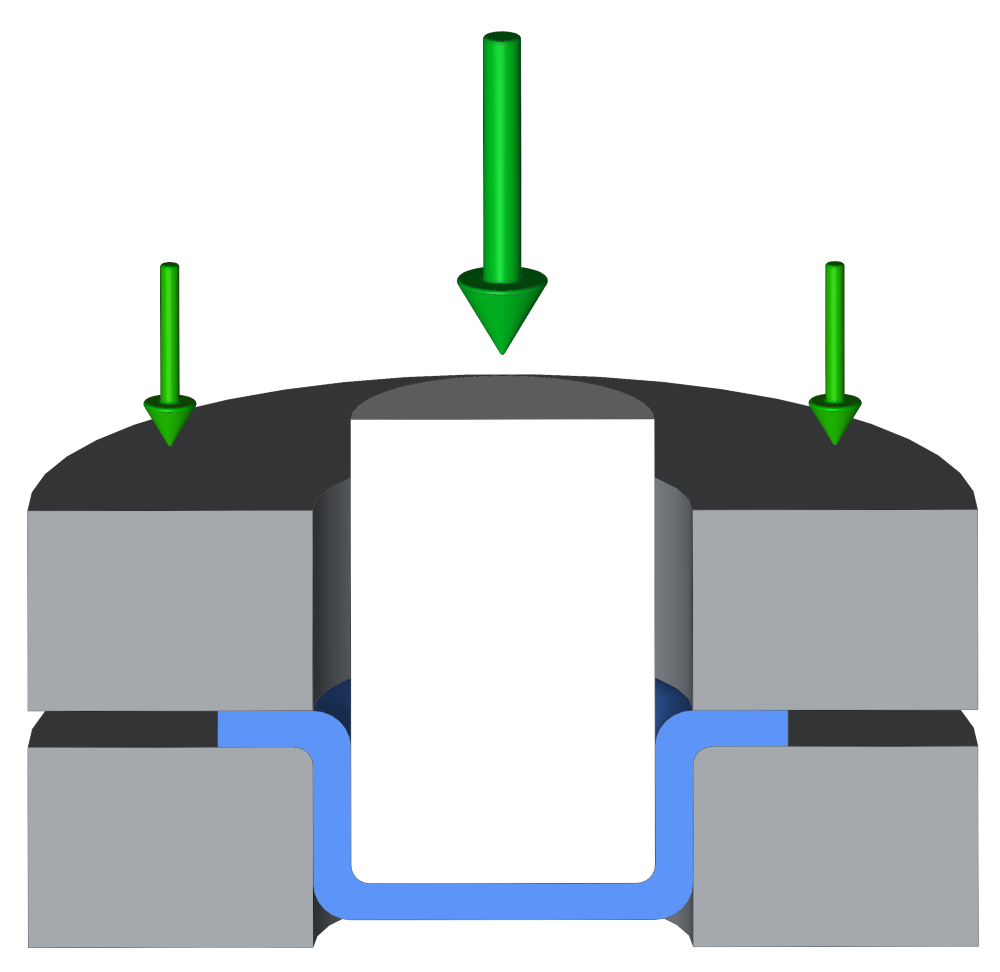

In stretching, the material is clamped and pushed through a mandrel into the hole. The result is that the material stretches and becomes thinner.

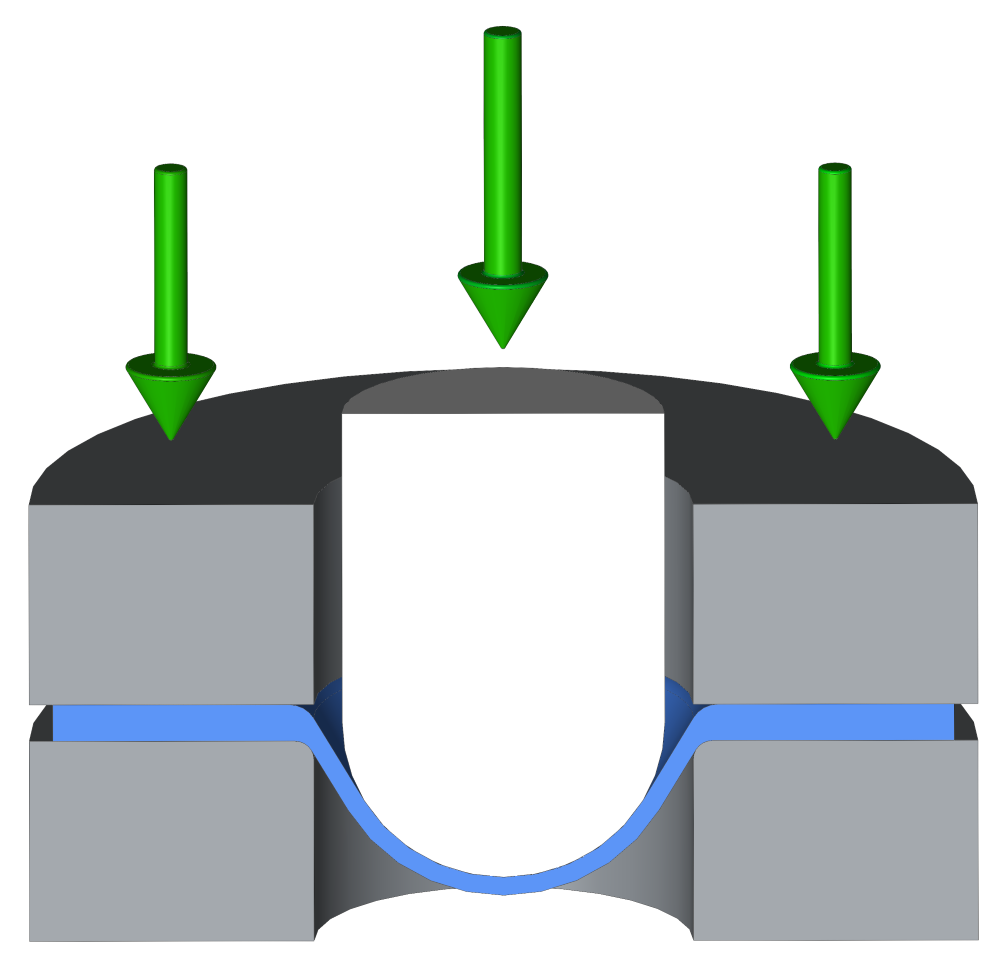

In deep drawing, the material is also clamped, but with a defined force which still allows the clamped material to move and “flow” into the hole. As the material is pulled into the hole and forced from a larger diameter to a smaller diameter, pressure is created in the material perpendicular to the direction of pull. The strain in the length direction is therefore compensated by the pressure in the width direction. As a result, the thickness of the material does not change. Thus, a product is made with a uniform wall thickness.

Deep drawing versus stretching

Many people confuse deep drawing with stretching; however, there is a fundamental difference between these techniques.

In stretching, the material is clamped and pushed through a mandrel into the hole. The result is that the material stretches and becomes thinner.

In deep drawing, the material is also clamped, but with a defined force which still allows the clamped material to move and “flow” into the hole. As the material is pulled into the hole and forced from a larger diameter to a smaller diameter, pressure is created in the material perpendicular to the direction of pull. The strain in the length direction is therefore compensated by the pressure in the width direction. As a result, the thickness of the material does not change. Thus, a product is made with a uniform wall thickness.

See the image below where the left is pulled deep and the right is stretched.

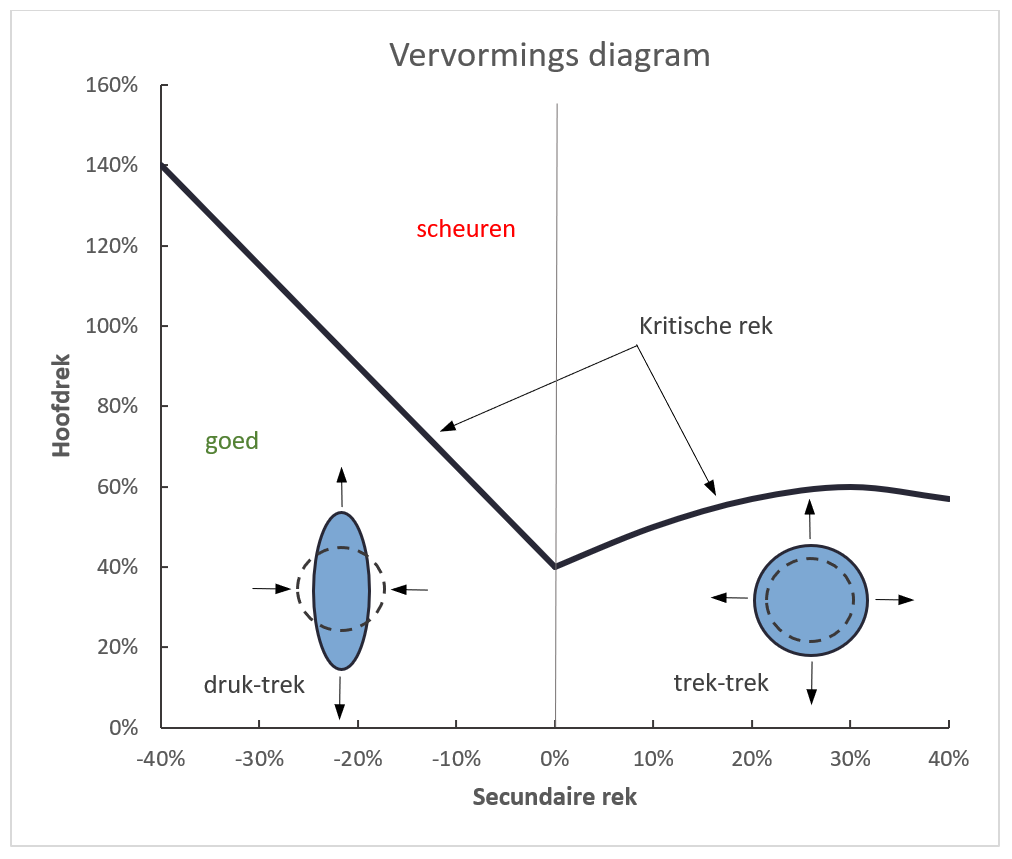

The deformation diagram below shows the difference of the two techniques well, through the stretching that occurs in the material during the process. Deep drawing on the left and stretching on the right. If a circle is drawn on the initial material, after deep drawing it will have become an ellipse of the same thickness and after stretching a larger circle that is thinner.