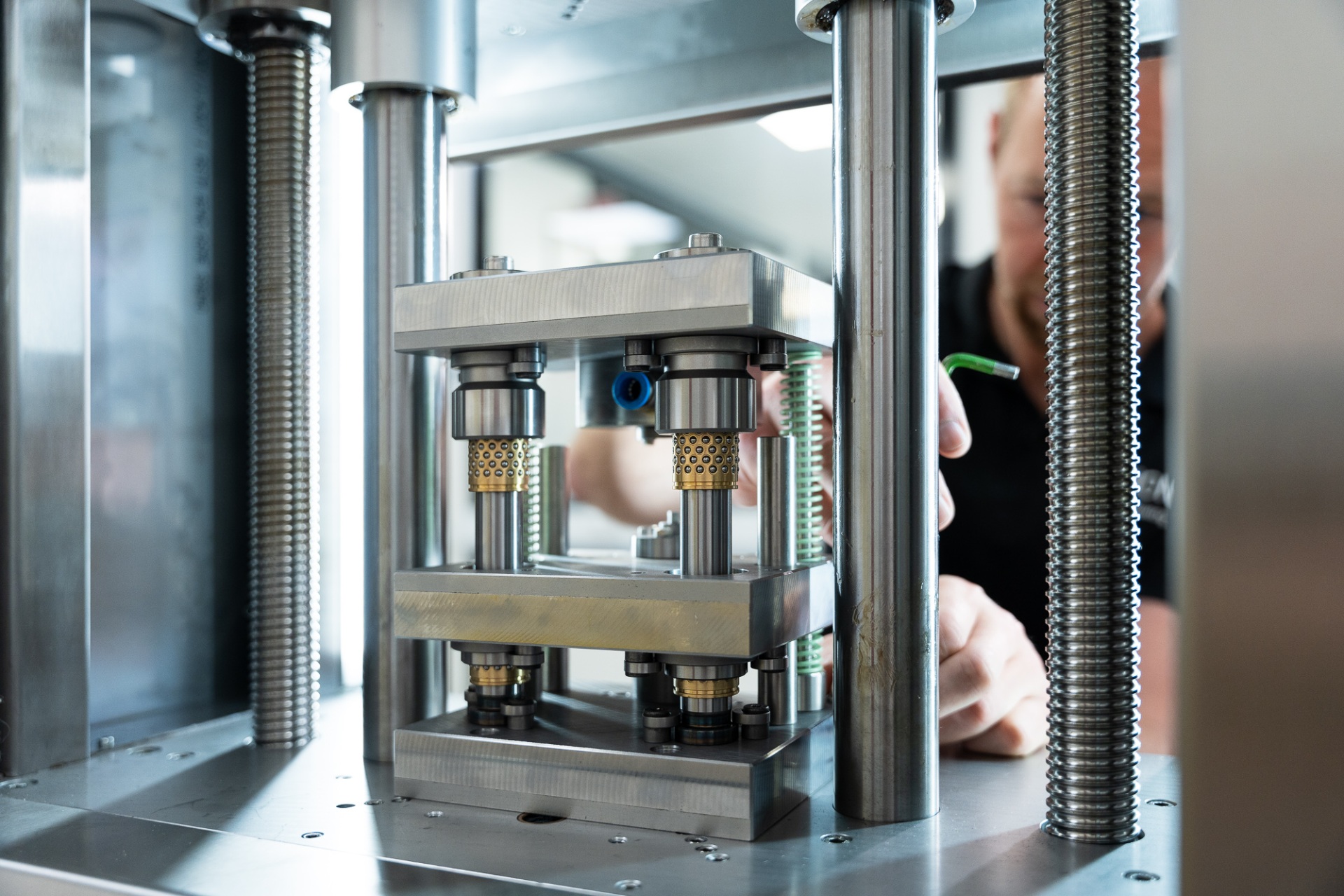

In-house tool shop for micro deep drawing

Micro deep drawing involves pushing a flat sheet into a shape. To push the sheet into a desired shape, we need the right tools that deform the material, each drawing step requires tools such as bend holders, dies, draw rings, ejectors and mandrels. After receiving the drawing and order, the first thing we do is design and fabricate the toolset. To shorten lead times, we have a versatile machine shop in-house to make the tools

Testing and making an initial prototype

Are the right tools in place? Then we create a prototype, an initial, testable version of the product. Does it work the way you want? Does it meet expectations? This way we can quickly see what improvements are needed and implement them before actual production can start. Testing ideas, discovering technical errors and processing feedback. This not only saves us time and costs in the development process, but also results in a reliable final product and manufacturing process.

The essence of micro deep drawing

A wide range of

deep draw products.

Below are some of the products we can realize using micro deep drawing. Think of nozzles, housings, sensors, covers, membranes, tubes and cannulas.

Shapes in products:

round, square, triangle

Low material loss

With scalable technology

Small series

up to 1 million pieces

Fully seamless and strong finished product