Is micro deep drawing suitable for your business?

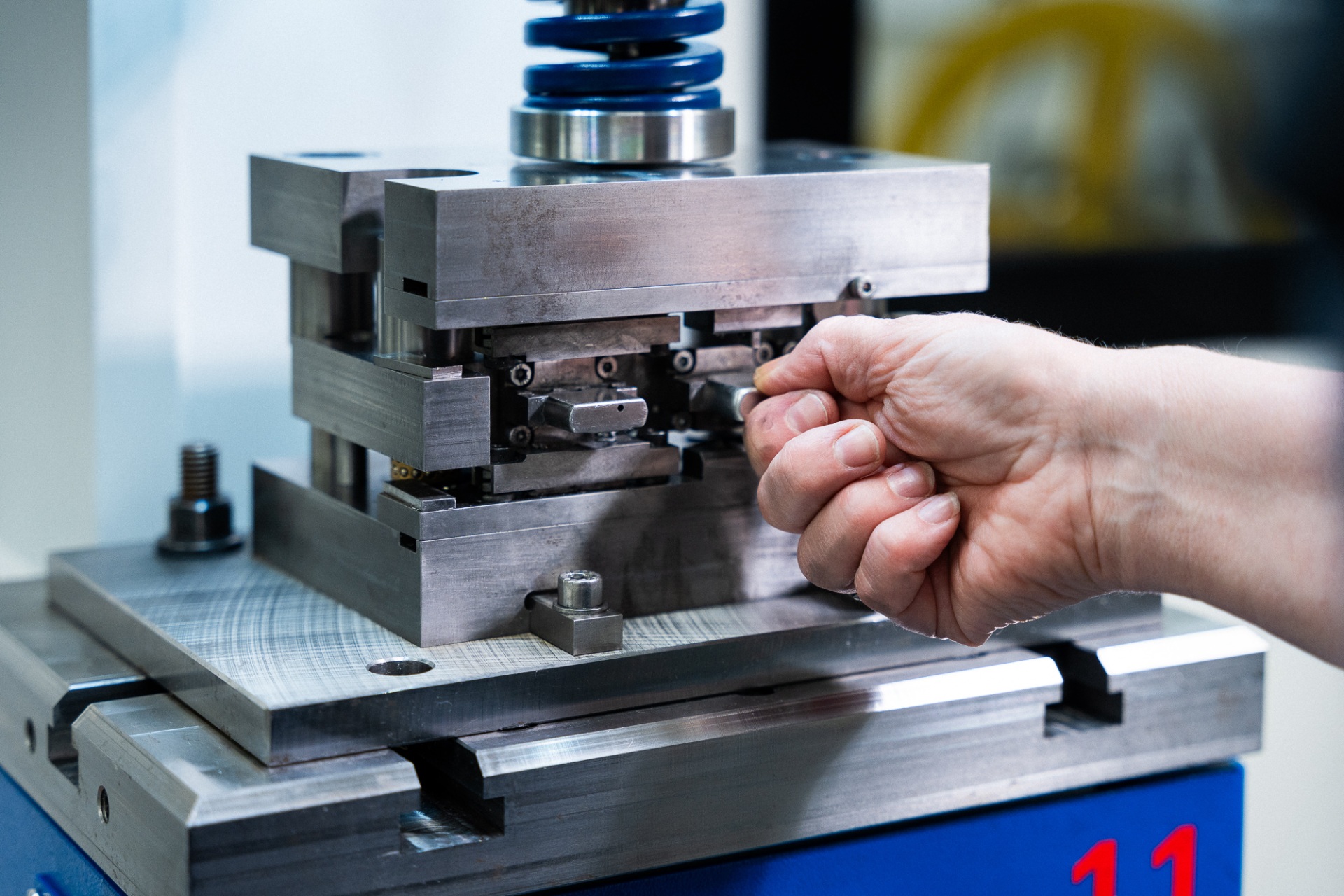

We manufacture high-quality parts by micro deep drawing for various industries. Micro deep drawing is used in various manufacturing applications. Why is it chosen? Because with micro deep drawing you save costs in material consumption, have high scalability and stable dimensions with high strengths.

high-tech

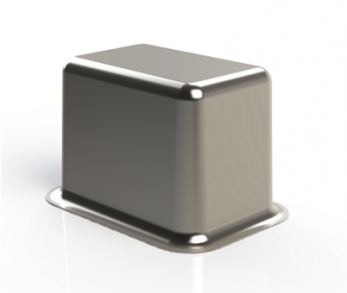

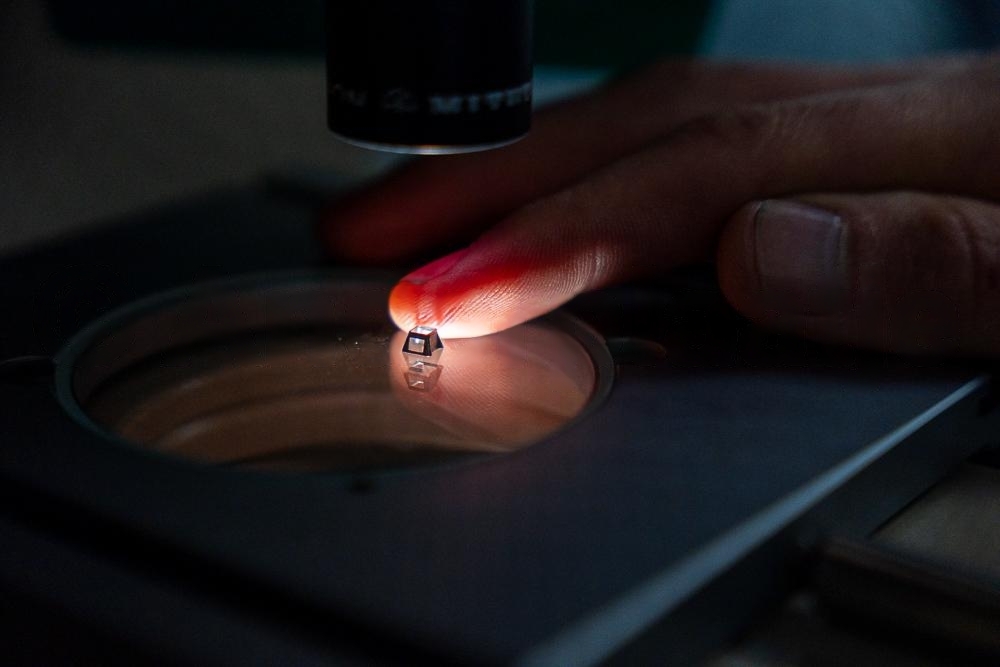

To protect sensors and electronics, a cap is often placed over the vulnerable components , micro deep drawing is ideally suited for this purpose. With micro deep drawing a suitable housing can be designed to meet all desired specifications. For example, sectors specialized in the measurement and detection of gases or liquids require high precision, special requirements for thermal conductivity and excellent corrosion resistance.

Micro deep-drawn components are often essential here due to the high strength, thin wall thicknesses and freedom of shape offered by the technology. Housings that support heat transfer, are airtight in gas measurements or protect vital components are just some of these applications.

medical sector

In the medical world, product requirements are becoming increasingly stringent and manufacturers must adhere to ISO 13485, an international standard for quality systems. Because of higher quality requirements on product properties and cleanliness, this has increased the use of single-use products. The scalable process of micro deep drawing is ideal for making these products affordably and in large quantities.

Many disposables are made with high-quality materials such as stainless steel and titanium, which may also be used inside or around the body. But also consider precious materials such as gold, silver, platinum, palladium, rhodium and iridium. Thus, we supply deep-drawn parts used as markers in the human body, as well as parts for implants or medical tools.

space

The ability to create thin-walled, high-strength products makes deep drawing ideally suited for aerospace. In aerospace, every gram of weight counts and products are often exposed to very challenging conditions. With deep drawing, many types of metals can be deformed, so there is always a match to be found for the requested application. Mubion can also help you manufacture smaller series, which is often requested in the aerospace industry.

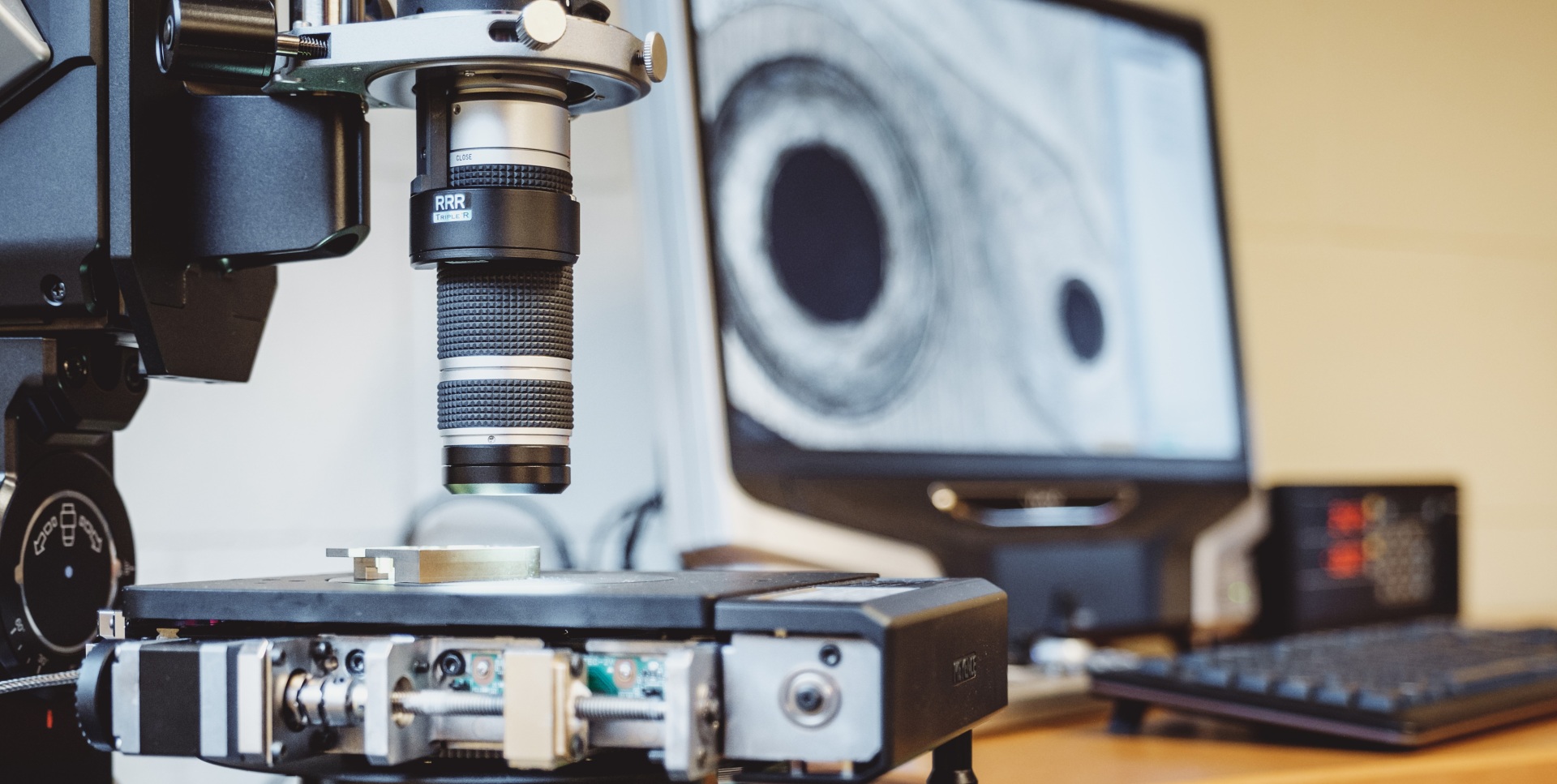

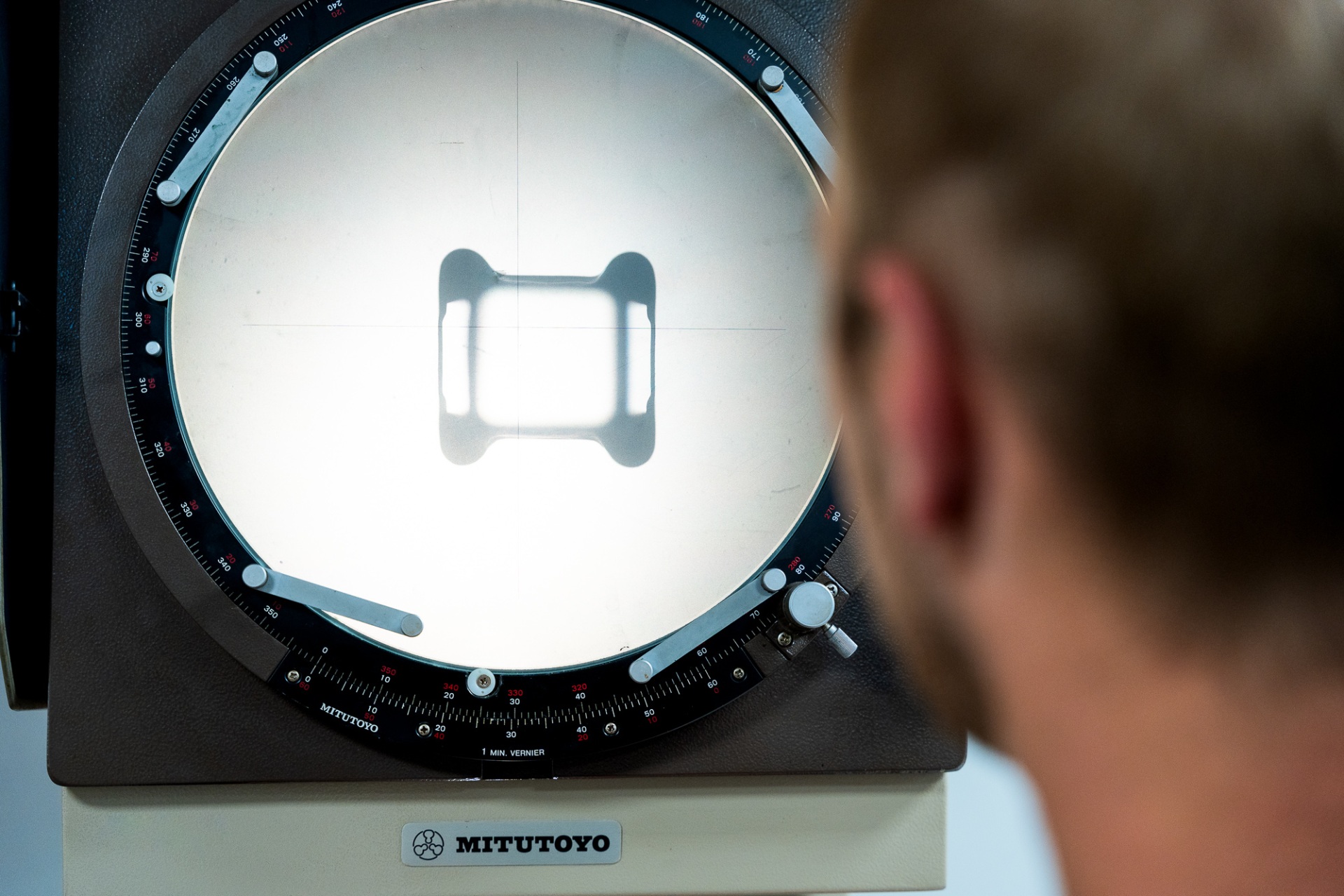

Sensor housings

Many of our deep-drawn products are used as enclosures in the medical or high-tech sectors. This is because deep drawing is easily scalable, has high consistency, is seamless, strong and has a lot of freedom of shape. With micro deep drawing we make enclosures very thin and light, something that milling and turning cannot do. We often work with high-quality corrosion-resistant materials such as stainless steel, titanium, copper and nickel.

Demanding applications where, for example, light, gases or liquids have to be analyzed are typical applications where deep-drawn enclosures are used. These include infrared and UV light in applications such as spectroscopy, radiometry and pyrometry.

A wide range of

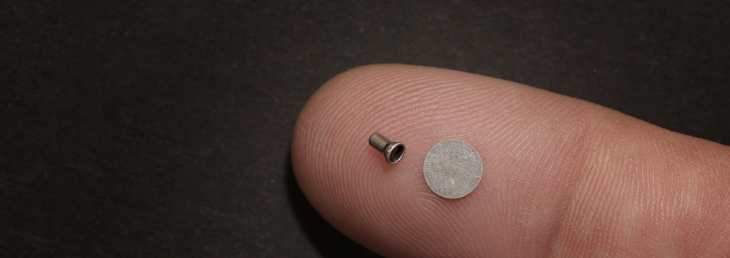

deep drawn parts

Below you can see some of the products we can realize using micro deep drawing. Think of nozzles, housings, sensors, covers, membranes, tubes and cannulas.